About Digital Printing

Table of ContentsSome Known Incorrect Statements About Digital Printing The Buzz on Digital PrintingThe Best Strategy To Use For Digital Printing

Digital printing also calls for very little configuration. Here are the key ways in which electronic printing supports greener practices: One of the substantial environmental advantages of electronic printing is lowering waste (Digital Printing). Standard printing methods, like lithographic printing, usually waste considerable amounts of paper and ink during the setup phase.

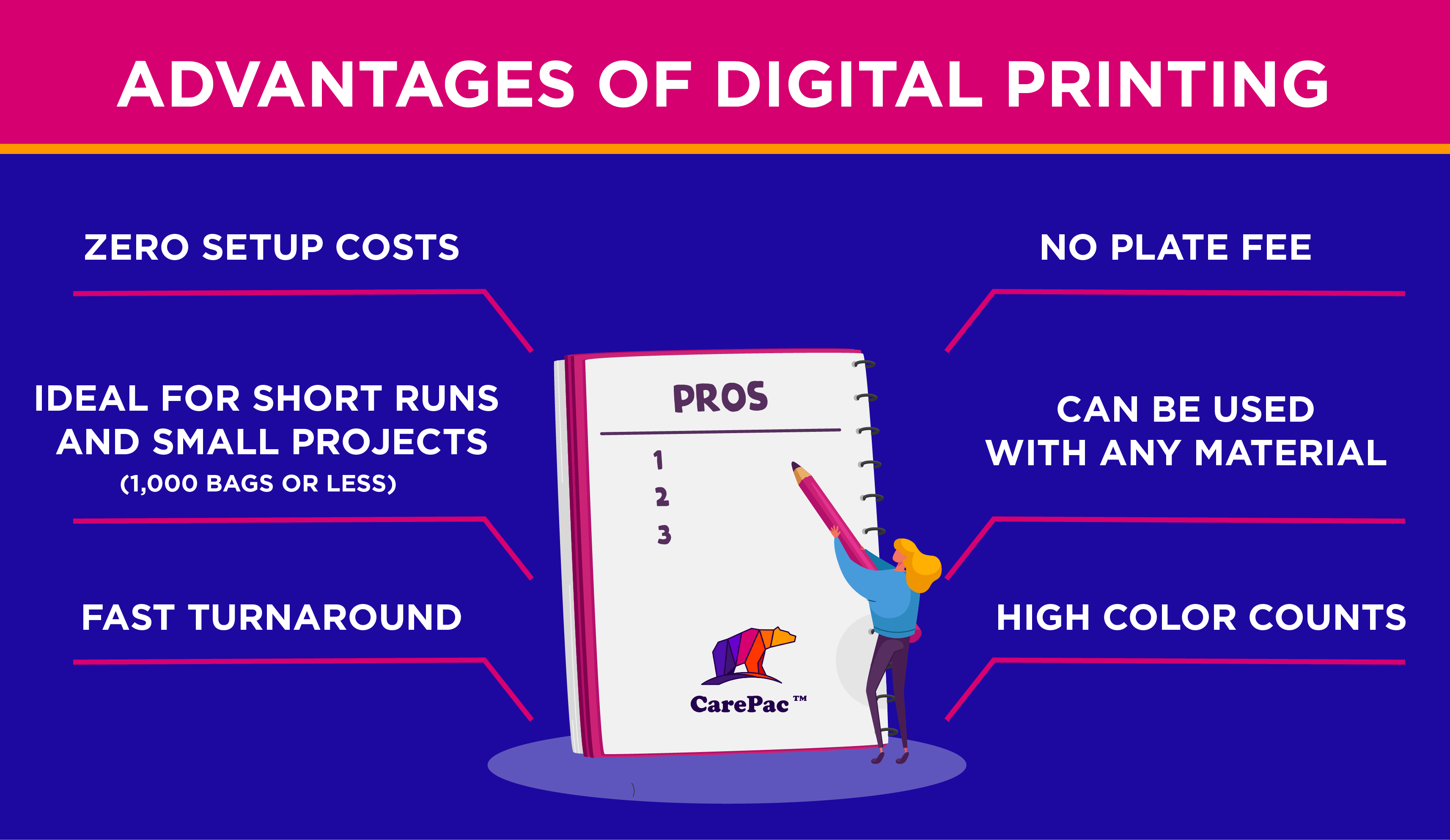

Digital printing machine get rid of the demand for these plates, substantially lowering setup costs. Digital printing machine can include variable information right into your prints, which enables for highly personalized marketing materials (Digital Printing). By individualizing your advertising and marketing materials, you can increase engagement with potential consumers and enhance the opportunities of converting them right into actual consumers

Digital printing presses supply outstanding shade uniformity and precision, causing better prints. With electronic printing, you can be certain that the shade of your prints will certainly be consistent from one print task to the following. Several years ago, many customers did decline direct-injection digital printing due to the fact that the high cost. The purchase expense of an established electronic printing equipment goes to least 150%of the standard printing and coloring devices, which enhances the.

The Best Strategy To Use For Digital Printing

In order to protect against rust of the nozzle, the ink for digital printing is a lot more costly than the ink for traditional printing, and additional ink purification is required throughout the printing process. In digital inkjet printing, the pattern is directly published on the material, eliminating the plate making in rotating screen printing. Yes, are much more pricey than standard printing inks, but the electronic printing process can conserve ink intake.

Today, the digital direct-injection printing press has gone from proofing to the stage of medium-sized and large-sized production. The electronic direct-injection machine has undergone the promo duration and went into the development and maturity duration. Both printing homes and brand owners recognize the advancement potential of electronic printing, and are prepared to boost financial investment in electronic printing. The print quality can often even rival that of balanced out printing. Digital printing is much more cost-effective for short print runs due to the fact that it requires less pre-press tasks and much less arrangement than balanced out printing. If a mistake in countered printing is not captured before home plates are made, it will be look at here really pricey to make brand-new ones. While every person sincerely wishes that errors will be avoided, it is practical to prepare for their potential improvement. Additionally, its precision is very high. This makes certain harmony in look throughout the board, decreasing the possibility that any item will certainly require to be thrown away due to flaws. Ensuring home plates remain in area, the ink trick is adjusted, and all the needed changes have been made is a lengthy process when offset printing. Lowered pre-press actions navigate to these guys mean much less time is required to establish up journalism at first. This leads to a significant velocity of turnaround time. When you need printed products see this rapidly, this is an excellent choice. Digital printing can be a lifesaver when you get an order in the nick of time.

Variable information printing, such as direct mail with customized codes and addresses, is preferably matched for digital printing. Digital fast printing only requires four steps of style, testimonial, printing and binding to get whatever done. Digital quick printing has an unparalleled advantage: print on need.

Comments on “What Does Digital Printing Mean?”